- Home

- Products

- Metalworking Lathe

- LYC series Gap Metal Lathe (Spindle Hole φ80mm)

LYC series Gap Metal Lathe (Spindle Hole φ80mm)

Introduction

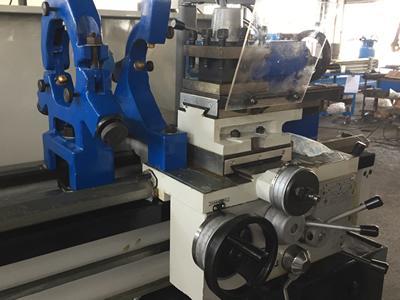

The LYC series metalworking lathe is used to produce cylindrical, bore, end face and conic parts, as well as drill holes, ream holes and pull oil grooves. It is often used to process in different measurement units, including metric, inch, module and pitch threads, making it suitable for high precision applications in low volume production and machine reparation plants.

This lathe can process steel, cast iron, nonferrous metals and nonmetal material. The precision and surface roughness of parts processed in this lathe reach level IT7 and 1.6, respectively.

It is easy to use this series due to the simple structure and high performance.

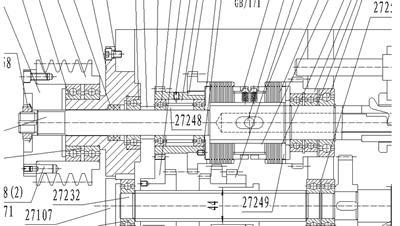

Characteristics- The quenched gear is processed through precise grinding, which ensures the lathe emits very little noise during operation.

- The lathe can process raw materials with three diameters due to the spindle holes being 65mm, 80mm and 103mm in diameter, respectively.

- The sliding box is equipped with forward and backward accessories, which controls the knife rest moving speed.

- The gear is protected in the gearbox due to the overload protection effect of the lead screw and polish rod.

- The lathe is available in various types: metric, inch, right hand maneuver wheel, multiple voltages, frequency, forward device and protective equipment that matches CE requirements.

| Item / Model | |||||

| Capacity | Max. swing over bed | 400mm | 450mm | 500mm | 600mm |

| Max. swing over cross slide | 225mm | 285mm | 325mm | 380mm | |

| Center distance | 1000,1500,2000mm | ||||

| Max swing over gap | 530mm | 580mm | 630mm | 730mm | |

| Effective length of gap | 260mm | ||||

| Bed width | 330mm | ||||

| Headstock | Spindle hole | 80mm | |||

| Spindle nose | ISO-C8 or ISO-D8 | ||||

| Spindle tapper | Metric 85mm | ||||

| Spindle speed (number) | 24-1600rpm | ||||

| Feed | Metric threads range (Kinds) | 0.5-28mm | |||

| Inch threads range (Kinds) | 1-56inch | ||||

| Module threads range (Kinds) | 0.5-35mm | ||||

| Diametral threads range (kinds) | 8-56D.P | ||||

| Longitudinal feeds range (kinds) | 0.072-4.038mm/rev (0.0027-0.15inch/rev) | ||||

| Cross feeds range (kinds) | 0.036-2.019mm/rev (0.0013-0.075inch/rev) | ||||

| Rapid trading speed of carriage | 5m/min (16.4ft/min) | ||||

| leadscrew size/ Diameter pitch | 35mm/6mm or 35mm/1/4 | ||||

| Slide plate | Cross slide travel | 300mm | |||

| Compound rest travel | 130mm | ||||

| Cross-section size of tool shank | 25×20mm (1×6/8inch) | 25×25mm | |||

| Tailstock | Taper of tall stock sleeve | Morse No.5 | |||

| Diameter of tall stock sleeve | 65mm | ||||

| Travel of tall stock sleeve | 120mm | ||||

| Motor | Main drive motor | 4.0kw or 5.5kw or 7.5kw | 7.5kw | ||

| Coolant pump motor | 0.125kw | ||||

| Rapid traverse motor | 0.12kw | ||||

| Packing size (L×W×H) | |||||

| Center distance | 1000mm | 2420×1150×1800mm(96×46×71in) | |||

| 1500mm | 2920×1150×1800mm (115×46×71in) | ||||

| 2000mm | 3460×1150×1800mm (137×46×71in) | ||||

| Net weight /Gross weight (kg) | |||||

| Center distance | 1000mm | 1640/2290kg | 1680/2330kg | 1770/2350kg | 1800/2500kg |

| 1500mm | 1850/2550kg | 1890/2590kg | 1910/2610kg | 2010/2760kg | |

| 2000mm | 2090/2860kg | 2130/2880kg | 2150/2920kg | 2250/3070kg | |

Standard Accessory

1. 3-jaw chuck

2. Driving plate

3. Center sleeve

4. Wrenches

5. Oil gun

6. Operation manual

Special Accessory

1. Steady rest

2. Follower rest

3. 4-jaw chuck

4. Face plate

5. Thread dial

6. Longitudinal automatic trip

7. Live center

8. Quick change toolpost

9. Taper copy ruler

10. 4-position longitudinal trip

Optional Accessories

1. Headstock structure with clutch

We supply the metalworking lathe with a mechanical brake machine tool that features a mechanical clutch and electromagnetic power off brake machine tool that utilizes a mechanical clutch. They meet Chinese standard GB15760-2004 or European standard 98/37/EC, 89/392EEC91/368EEC.

2. Foot brake and electromagnetic brake

3. Slip-hand maneuvering wheel (left-hand turn maneuver wheel and left-hand turn maneuver wheel with metric or inch calibration loop and single-scale or double scale).

4. CE protective equipment (chuck protection, tool-post protection and leadscrew protection can be chosen).

Factory

Index

metal turning lathe, metal spinning lathe, metal machining

SJR Machinery (Shanghai FTZ) Limited

Add.: Room 210, 2rd Floor of Hongnan Investment Building, No.939, Jinqiao Road, Shanghai

Tel.:

+86-513-81105908

Fax: +86-513-85220972