- Home

- Products

- Metalworking Lathe

- CC series Gap Metal Lathe (Spindle Hole φ52mm)

CC series Gap Metal Lathe (Spindle Hole φ52mm)

Introduction

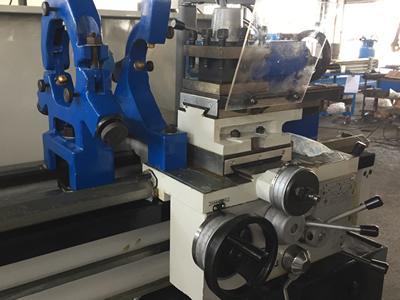

The CC series metalworking lathe is used to produce cylindrical, bore, end face and conic parts, as well as drill holes, ream holes and pull oil grooves. It is often used to process in different measurement units, including metric, inch, module and pitch threads, making it suitable for high precision applications in low volume production and machine reparation plants.

This lathe can process steel, cast iron, nonferrous metals and nonmetal material. The precision and surface roughness of parts processed in this lathe reach level IT7 and 1.6, respectively.

It is easy to use this series due to the simple structure and high performance.

Characteristic- The slide way of lathe bed uses a super audio frequency induction heating and quenching, giving the lathe its long service life.

- The slide way operates through turning, giving it a higher precision.

- The gear inside the spindle box is processed using precise turning, which means operation emits little to no noise.

- This lathe can be used to process workpieces with threads.

- The feeding box stores oil, which is used for lubrication.

- The lathe is safe and reliable due to the electric elements housed in a specialized electrical cabinet.

- The lathe is easy to operate, as it is equipped with both a foot brake and electromagnetic brake.

- The sliding box is equipped with forward and backward accessories, which control the movement speed of the knife rest.

| Item and Model | ||||

| Processing capacity | Max swing over bed | 360 | 400 | 500 |

| Max swing over cross slide | 190 | 230 | 330 | |

| Max swing over gap | 520 | 560 | 660 | |

| Center distance | 750mm | 1000mm | 1500mm | |

| Bed width | 360 | |||

| Spindle | Spindle hole | 52mm | ||

| Spindle nose | C6 | |||

| Spindle taper | MT6 | |||

| Spindle speed (number) | 40-1400rpm (9 Steps), 1600rpm need special order | |||

| Feeding | Metric threads range (Kinds) | 0.25-14mm (19 Kinds) | ||

| Inch threads range (Kinds) | 2-40/inch | |||

| Module threads range (Kinds) | 0.5-3.5mm (11kinds) | |||

| Slide plate | Cross slide travel | 180mm | 222mm | |

| Compound rest travel | 95mm | |||

| Cross-section size of tool shank | 20×20mm² | |||

| Tailstock | Taper of tall stock sleeve | MT4 | ||

| Diameter of tall stock sleeve | 65mm | |||

| Travel of tall stock sleeve | 140mm | |||

| Main motor power | 4KW | 5.5KW | ||

| Packing size (L×W×H) | ||||

| Center distance | 750mm | 2220×1150×1590mm | ||

| 1000mm | 2470×1150×1590mm | |||

| 2500mm | 2970×1150×1590mm | |||

| Net weight /Gross weight (kgs) | ||||

| Center distance | 750mm | 1350/2000 | 1400/2050 | 1500/2150 |

| 1000mm | 1450/2100 | 1500/2150 | 1600/2250 | |

| 1500mm | 1600/2250 | 1650/2300 | 1750/2400 | |

Standard Accessory

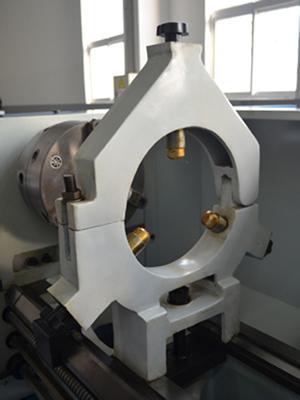

1. 3-jaw chuck

2. Centre & centre sleeve

3. Wrenches

4. Bolts

5. Oil gun

Special Accessory

1. Steady rest

2. Follower rest

3. 4-jaw chuck

4. Face plate

5. Operation manual

3. Slip-hand maneuvering wheel (left-hand turn maneuver wheel and left-hand turn maneuver wheel with metric or English calibration loop and single-scale or double scale).

4. CE protective equipment (chuck protection, tool-post protection and leadscrew protection can be chosen).

FactoryIndex

metal lathe, metal spinning, precision machining

SJR Machinery (Shanghai FTZ) Limited

Add.: Room 210, 2rd Floor of Hongnan Investment Building, No.939, Jinqiao Road, Shanghai

Tel.:

+86-513-81105908

Fax: +86-513-85220972